S3 Harohalli

OverviewStanzen started its operation in S3 Harohalli on 10th February 2022.

Equipped with advanced infrastructure, our S3 Harohalli facility strengthens our capabilities in producing high precision stampings for critical automotive safety applications. This unit reflects our unwavering commitment to quality, precision and on-time delivery, while ensuring we meet the evolving needs and standards of the automotive industry.

Products

At Stanzen, innovation and customer satisfaction remain at the core of everything we do. We continuously enhance our capabilities to empower and support the success of our partners in the automotive industry.

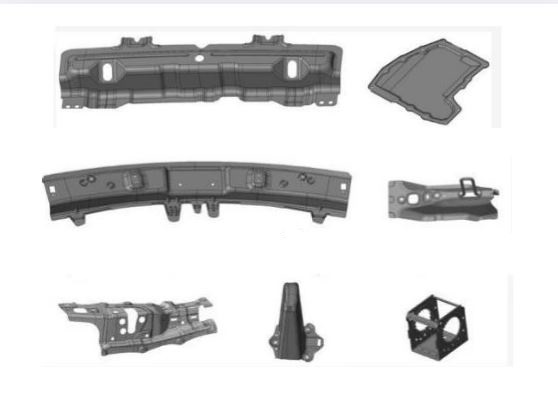

Types of Components Manufactured:

Door, Body & Assembly Parts Seat Belt Frame, Cyclops and Strap Inverter Cover Parts

Press Shop

Our Press Shop is equipped with a wide range of Tandem and Progressive presses to meet diverse stamping requirements. The setup includes Tandem H frame C line press 400T to 300T – 4 machines, Tandem C Frame D line press 250T to 200T – 7 machines, Progressive H frame C line Press 400T – 1 machine, Progressive C frame D line Press 200T – 3 machine. This versatile capacity allows us to handle both high-volume production and precision components, ensuring consistent quality, dimensional accuracy and on time delivery for our customers across automotive and engineering sector.

Weld Shop

Our welding facilities are equipped with a balanced mix of automated and manual systems to deliver reliable and high-strength assemblies. The setup includes Spot Robots (3) for precision and consistency, along with Manual Nut and Stud Welding stations (12) and Manual Spot Welding stations (2) to handle specialized and complex operations. This combination enables us to achieve superior weld quality, production flexibility and adherence to stringent automotive standards.

Have a question? Call us now

Office : 080 – 4010 8850

Need support? Drop us an email

info@stanzen.in

We are open on

Mon – Sat 9am to 5.30pm

Sunday – Closed